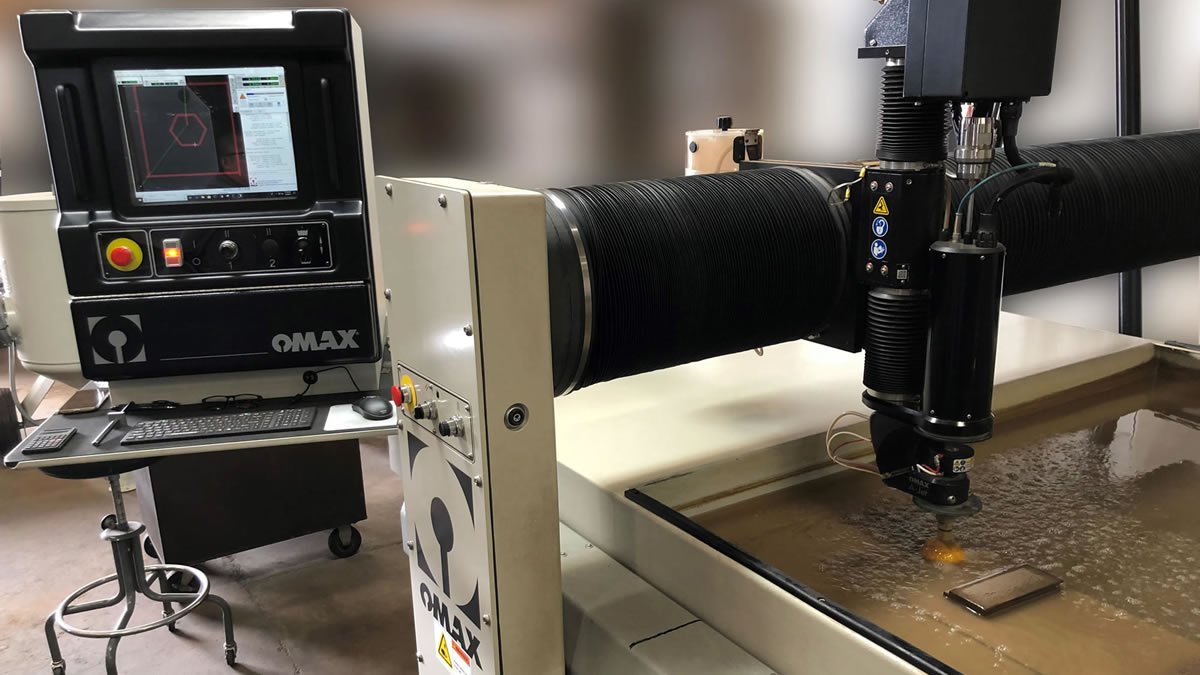

OMAX Waterjet Cutting

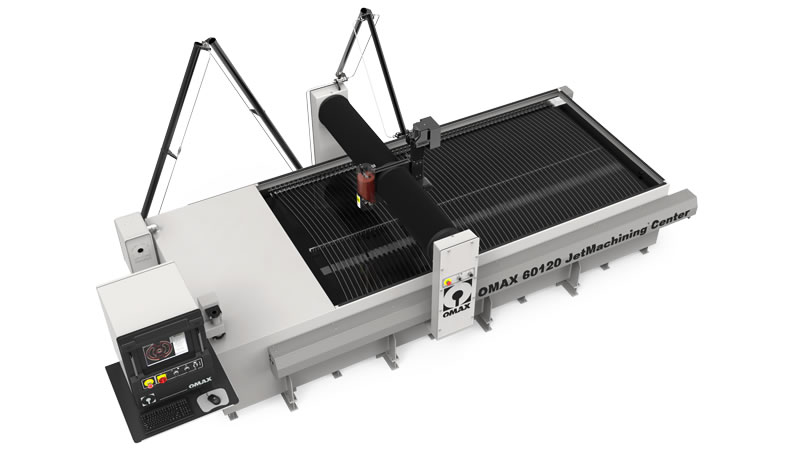

Fleming Metal Fabricators utilizes the OMAX 60120 Precision Bridge Style Abrasive Waterjet which cuts complex parts in a wide range of materials and thicknesses and up to 5’ x 10’ in sheet size. A-Jet 5-axis linear drive leaves a satin-smooth edge.

OMAX Waterjet Cutting Capabilities

- Stainless Steel

- Aluminum

- Exotic Metal

- Carbon Steel

- Alloy Steel

- Red Metal

- Composite / Laminate

- Ballistic Plate

- Plastic

- Rubber

- Stone

OMAX Waterjet Cutting Features

- Computer control software integrated CAD/CAM system directly uses drawing or DXF files.

- Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics.

- Extremely hard, reflective and nonconductive materials can also be cut.

- Environmentally “green” system uses only natural garnet abrasive and water in the cutting process.

- No noxious fumes, liquid or oils used in, or caused by, the machining process.

- Leaves behind a satin-smooth edge, reducing secondary operations.

- Does not create heat-affected zones or mechanical stresses.

- Eliminates secondary machining and grinding for fabrication processes, ideal for common welding projects.

- Precision angular motion can create unique 3D parts.

- Fully automatic taper compensation to minimize taper on finished parts.

- OMAX-unique High Angle Fusible Mixing Tube protects precision mechanism.